Rubber and Elastomers

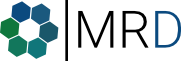

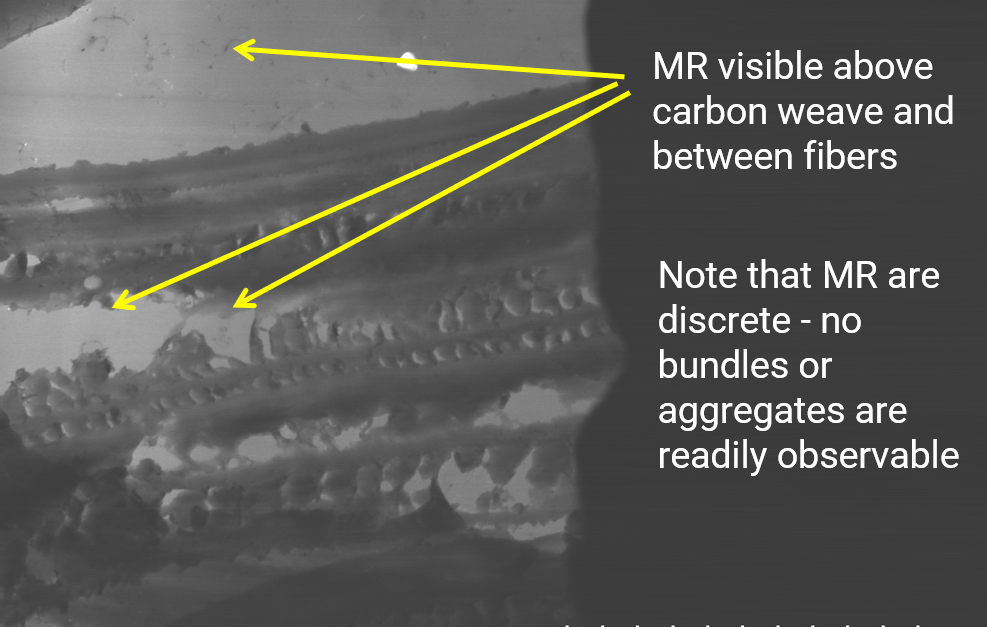

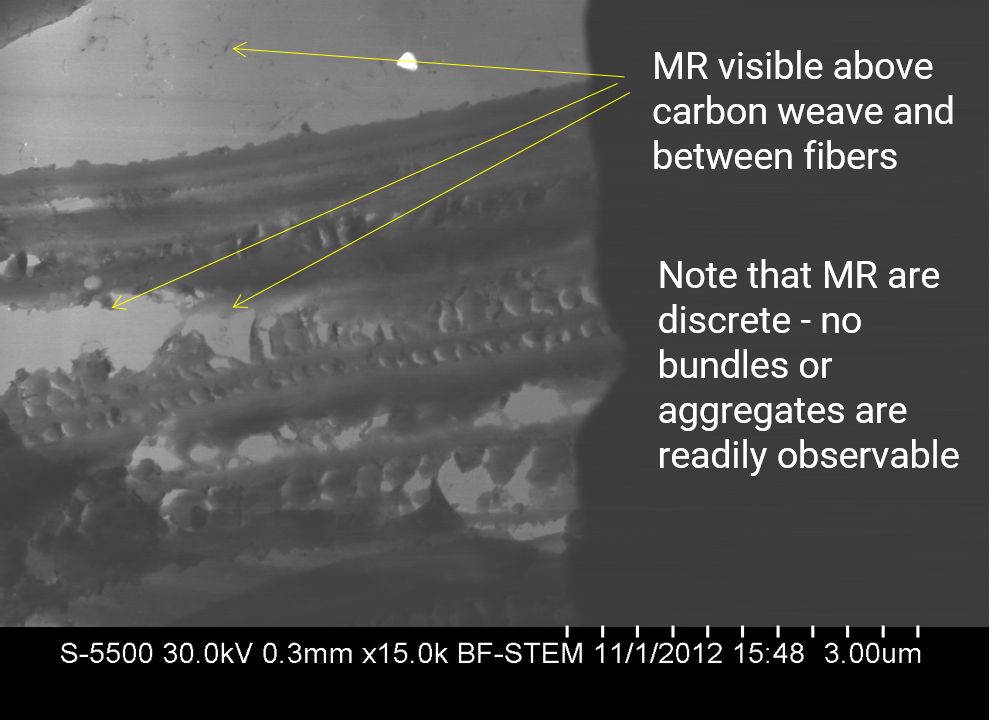

Molecular Rebar®, MR, increases wear resistance to extend the lifetime of rubber goods and tires. MR’s optimal aspect ratio and excellent dispersion improve crack propagation resistance, often doubling lifetime in macro-abrasive conditions.

Lowered cost of component ownership ($/hr)

- Less downtime & higher throughput

- Longer lifetime than cost increase = lower operating cost

Easy fit with existing manufacturing

- MR in oil: MRO

- Universal uses, no change in compounding process

- 50:50 or 60:40 ratio of MR to oil available

- MR in oil: MRO

Improved performance properties

- Lighter-weight, more fuel efficient, and tougher rubber compounds for tires

By leveraging the improved resistance to wear, tire treads can be optimized through engineering design changes. Allow Molecular Rebar® to be a new ingredient in your recipe cabinet.

Performance & Products

30%+ BF Goodrich Cut & Chip resistance

15%+ tear resistance

No increase in rolling resistance

MRO Gen I

- Use in specialty polymers: NBR/HNBR or FKM/FFKM

- Delivered with TOTM, DOP, or DBS oil

- DBEEA, DOA oil offering in the future

MRO Gen II

- For use as an additive for toughness properties in parts & tires

- Use in NR/SBR/PBR

- Offered as a 50:50 ratio of MR:Oil in naphthenic, RAE, or soybean oil

- TDAE, RAE oil offering in the future

MRO Gen III

- For use as a carbon black or reinforcing filler replacement, lowering density and improving performance

- Use in NR/SBR/PBR

- Offered as a 60:40 ratio of MR:Oil in naphthenic, RAE, or soybean oil

Performance & Products

30%+ BF Goodrich Cut & Chip resistance

15%+ tear resistance

No increase in rolling resistance

Molecular Rebar in Naphthenic or TDAE oil (MRO)

- Use in NR/SBR/PBR

Molecular Rebar in TOTM- MR 1020 DLC

- Use in NBR/HNBR

Molecular Rebar in FKM/FFKM

- Produced with customer elastomer

- Developmental product

Coatings

Molecular Rebar® makes coatings more rugged and corrosion resistant. Our functionalized MR binds to epoxy or urethanes for improved durability. MR electrically connects corrosion inhibitors and reduces the required zinc concentration in zinc-rich primers. Because MR is discrete and individual, coatings are defect-free.

Reduced cost of ownership

- Longer corrosion protection lifetimes

- Increased damage tolerance

Reduced coating cost

- Thinner coatings

- Reduced corrosion inhibitors

Increase market share for coating manufacturers

- Differentiated coatings

- Replace 90% Zinc-rich primers with 80% Zinc or less

Coatings

Molecular Rebar® makes coatings more rugged and corrosion resistant. Our functionalized MR binds to epoxy or urethanes for improved durability. MR electrically connects corrosion inhibitors and reduces the required zinc concentration in zinc-rich primers. Because MR is discrete and individual, coatings are defect-free.

Reduced cost of ownership

- Longer corrosion protection lifetimes

- Increased damage tolerance

Reduced coating cost

- Thinner coatings

- Reduced corrosion inhibitors

Increase market share for coating manufacturers

- Differentiated coatings

- Replace 90% Zinc-rich primers with 80% Zinc or less – epoxy producers increase sales

Longer Lifetime

Performance & Products

Available Products

-

2% Molecular Rebar® in bisphenol A/epichlorohydrin liquid epoxy resin

Higher Impact Strength

Longer Lifetime

Higher Impact Strength

Performance & Products

Available Products

-

2% Molecular Rebar® in bisphenol A/epichlorohydrin liquid epoxy resin

Conductive Inks

MOLECULAR REBAR® is uniquely tailored to take your conducting ink formulations to the next level of rugged performance for rapid growth into flexible/durable applications with economics that make sense.

Improved print quality & performance

- Improved conductivity at lower thickness

- Improved performance consistency- less rejects

- Improved conductivity during stretching

- Improved print resolution

Easy fit with printing processes

- Nano- to Micro-particle inks

- Digital to screen printing

Conductive Inks

MOLECULAR REBAR® is uniquely tailored to take your conducting ink formulations to the next level of rugged performance for rapid growth into flexible/durable applications with economics that make sense.

Improved print quality & performance

- Improved conductivity at lower thickness

- Improved performance consistency- less rejects

- Improved conductivity during stretching

- Improved print resolution

Easy fit with printing processes

- Nano- to Micro-particle inks

- Digital to screen printing

Performance & Products

Enhanced

- Toughness and durability in epoxies

- Interlaminar shear stress between fibers

Fit easily with existing composites manufacture.

- Does not change curing conditions

- Masterbatch designed for facile dilution.

- Little flow viscosity changes

- Enhanced microwave or near infra red curing kinetics

Performance & Products

Enhanced

- Toughness and durability in epoxies

- Interlaminar shear stress between fibers

Fit easily with existing composites manufacture.

- Does not change curing conditions

- Masterbatch designed for facile dilution.

- Little flow viscosity changes

- Enhanced microwave or near infra red curing kinetics