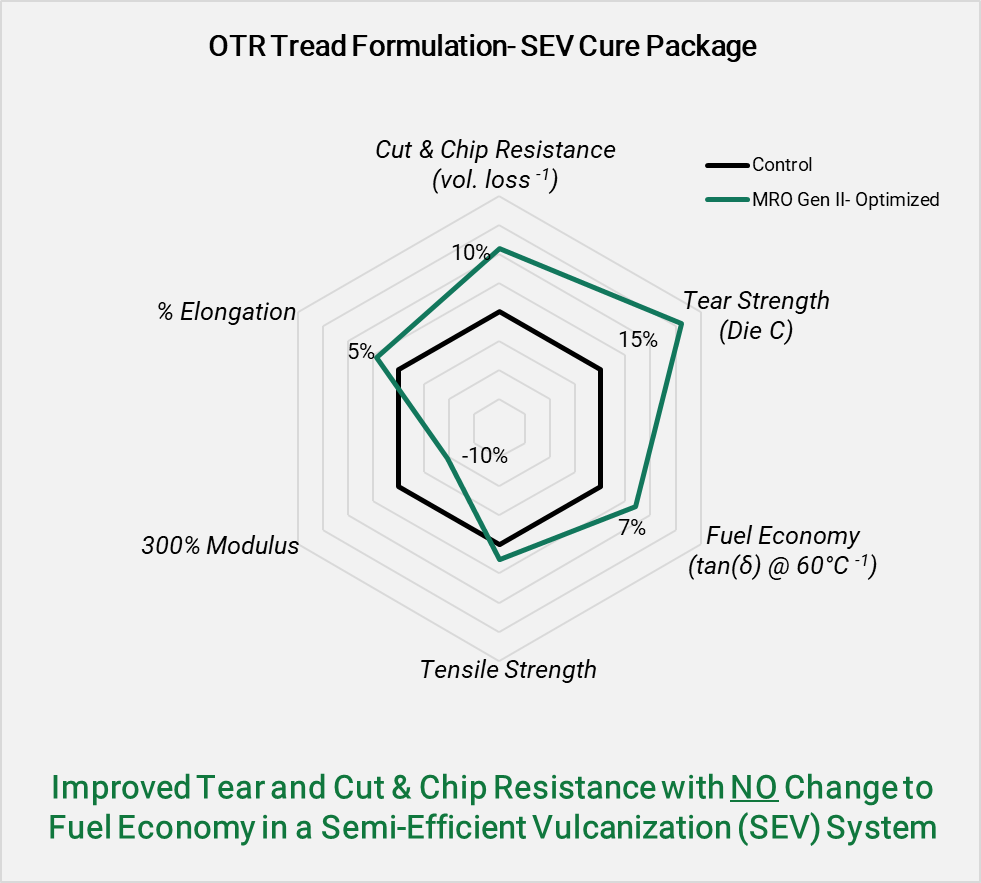

MRO Gen II in a Semi-efficient Vulcanization (SEV) Off-the-road (OTR) Tire Tread Formulation

As part of the ongoing product qualification and initial market adoption for MRO Gen II, MRD has embarked on various benchmarking laboratory studies. A common inquiry is the use of MRO Gen II in a SEV cure package system, as the benefits given by such a cure system are beneficial for quicker-moving OTR/TBR tire treads. Previously, MRD demonstrated consistently improved cut & chip resistance (along with other physical benefits) in a conventional vulcanization (CV) cure package system. This experiment demonstrates a similar level of benefit in wear resistance in this SEV system, as in the previous conventional (CV) system. MRO Gen II can be used in an NR-BR OTR SEV tread formulation to improve cut, chip, and chunk resistance without negatively affecting dynamic properties, such as rolling resistance.

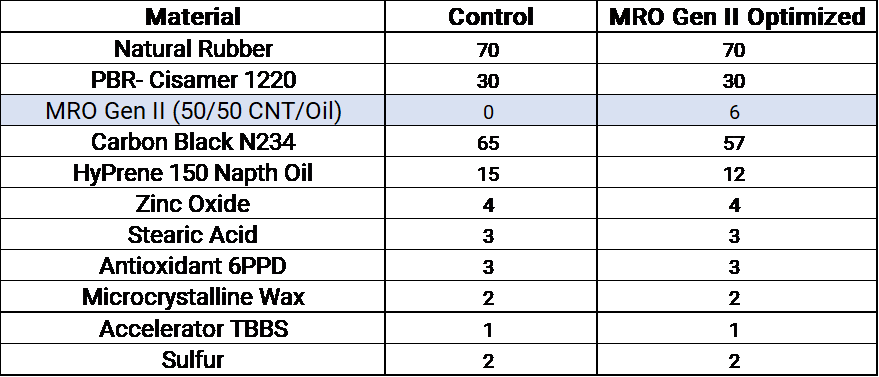

MRO Gen II was mixed into this typical natural rubber / polybutadiene rubber (NR-BR) OTR tread formulation using standard rubber processing techniques. The formulations are shown below. It should be noted that the formulation with MRO Gen II is optimized for equivalent oil content and roughly equivalent filler surface area, by reduction of the existing oil content and the N234 carbon black, respectively.

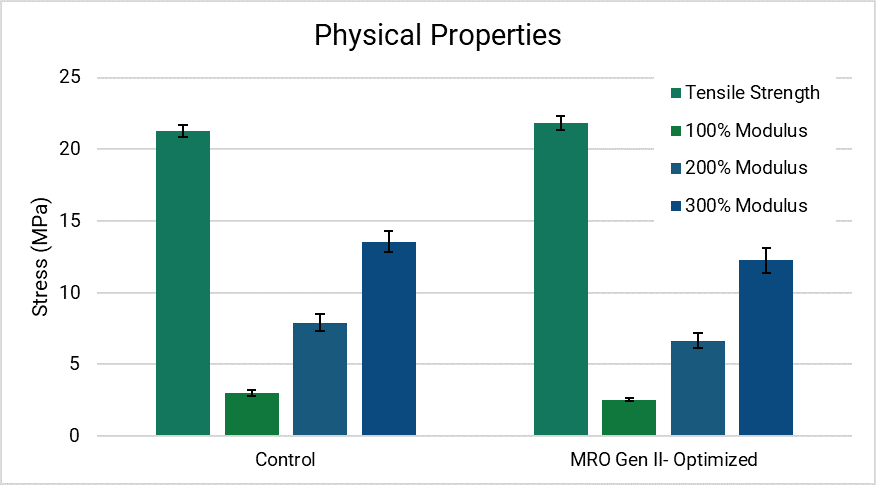

Tensile properties were largely unchanged with the use of the multiwall carbon nanotubes. The tensile strength and % elongation were slightly improved, and the moduli values were slightly depressed.

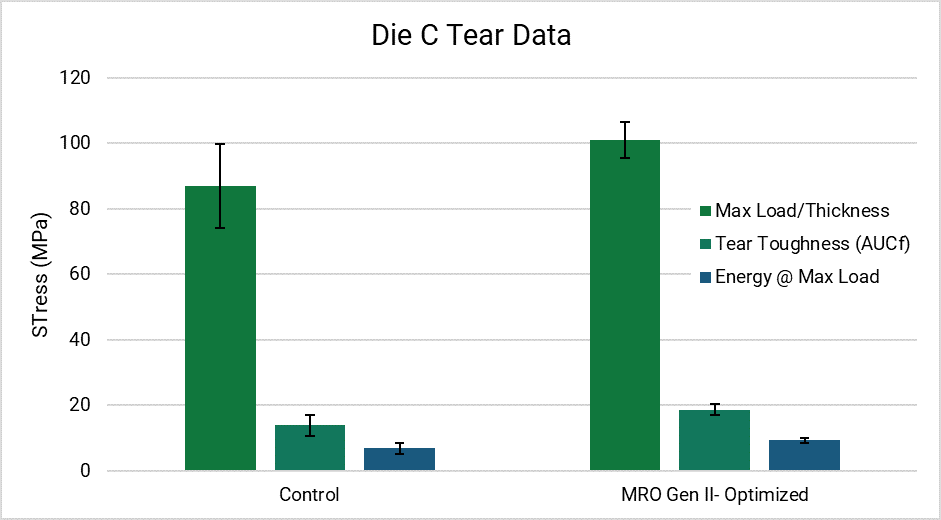

Die C tear properties were improved significantly with the use of the MRO Gen II, resulting in a higher peak tear strength, and a higher tear toughness.

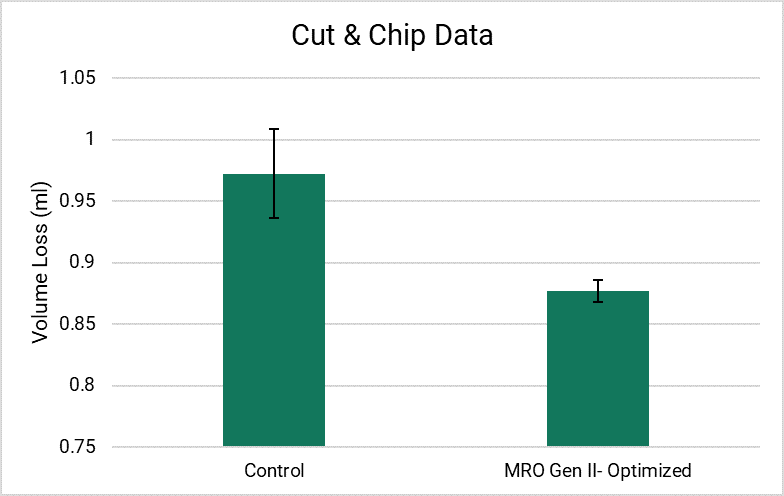

Cut & chip resistance was improved (i.e. less volume loss), as expected, although less improved than in the conventional vulcanization (CV) cure package experiment. There may be some interaction between the carbon nanotubes and the sulfidic linkages, whether they be mono- or poly- sulfidic.

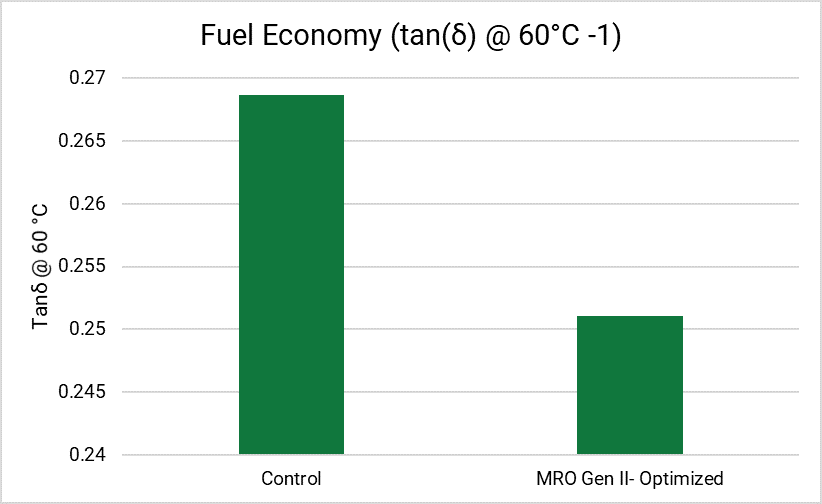

Rolling resistance (RR) indicator produced via dynamic mechanical analyzer (DMA) at 10% strain, 10 Hz, and 60 °C, showed a slight improvement when the formulation was optimized for MRO Gen II usage.

It is expected that an OTR tire produced with MRO Gen II would have a greater resistance to macro-abrasion, such as cutting & chipping, while maintaining existing dynamic properties, i.e. fuel economy. MRO Gen II can enable higher-performing tires for tough environments and specialty applications- improving tire life and reducing operating cost per hour while keeping the expected fuel economy of a SEV tire tread.