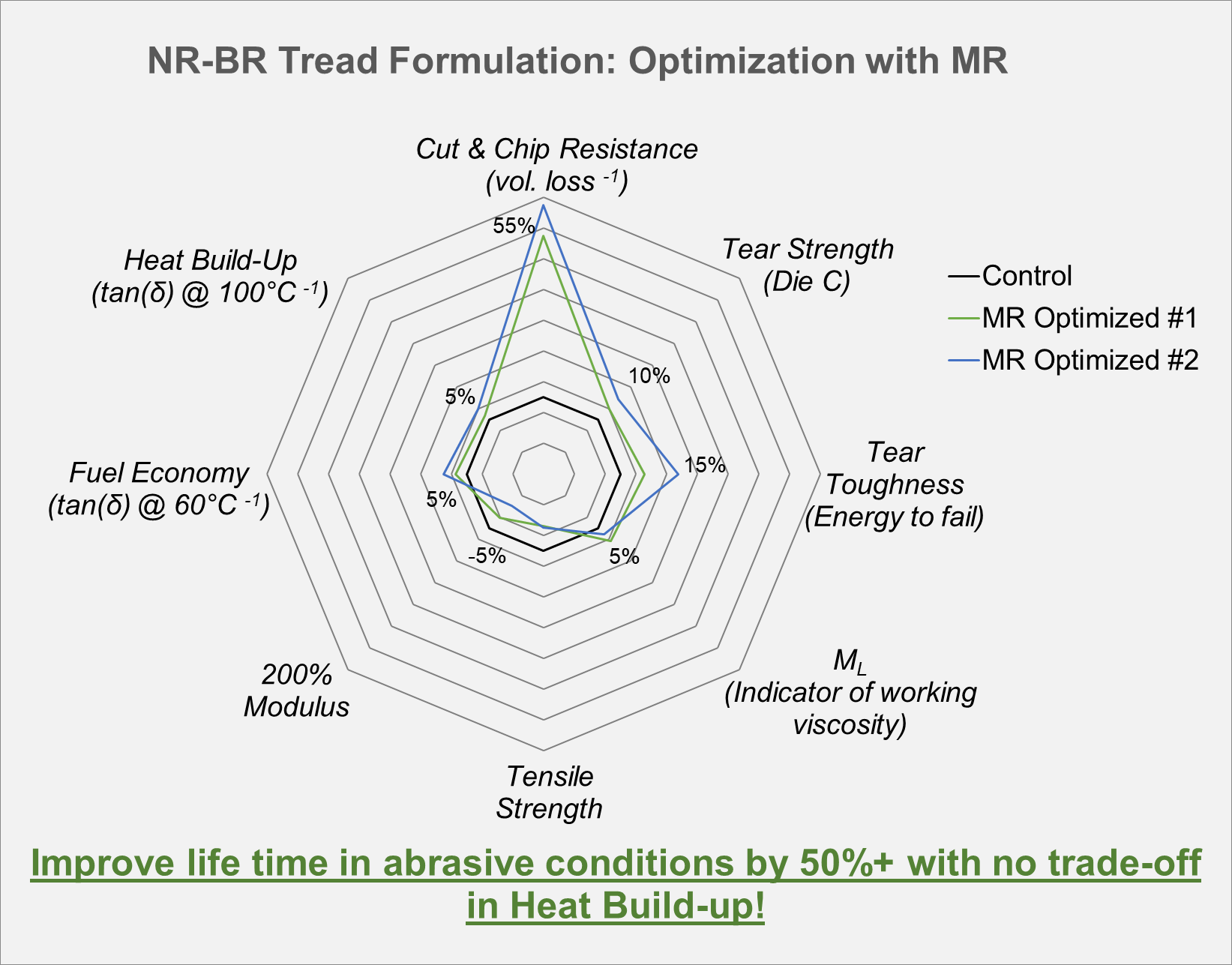

MRD releases 2nd generation product: MRO Gen II

Improved C&C with NO change in Fuel Economy or Heat Build-Up

MRO Gen II is a pelletized powder consisting of 50% multiwall carbon nanotubes and naphthenic oil. Molecular Rebar (MR) are functionalized and discrete multi-wall carbon nanotubes. Gen II MR is surface modified, promoting better interactions with non-polar systems, such as natural rubber. These CNTs disperse within an elastomer compound using standard rubber processing methods and machinery, often an internal mixer or 2 roll mill. MRO can be added directly to a formulation or can replace some portion of conventional fillers to optimize a formulation. MR’s reinforcing qualities within the elastomer compound lead to improved wear, tear, and cut & chip resistance, with no change to rolling resistance or heat build-up.

Commercial Viability

- Drop-in product – no change in typical processing

- >100 MT/yr capacity for MR production

- Multiple supply sources of raw MWCNTs

- TS&D lab to help optimize customer formulas

- Improved performance = value down the chain

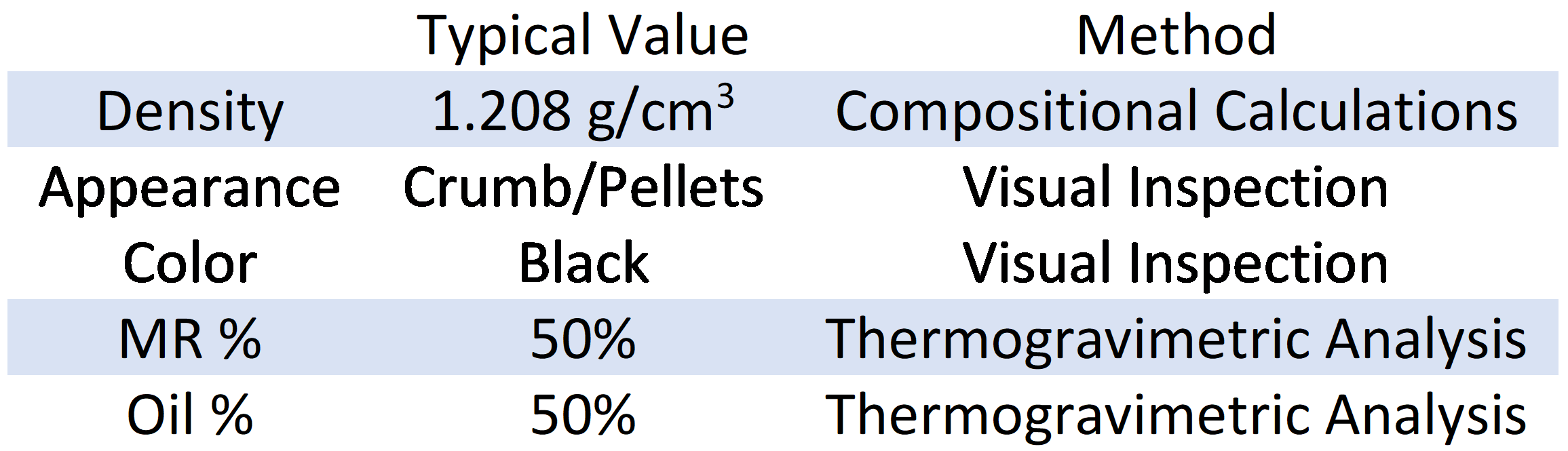

Product Characteristics